SLADE

Top-Rated Slade Graphite Yarn Distributors Near You

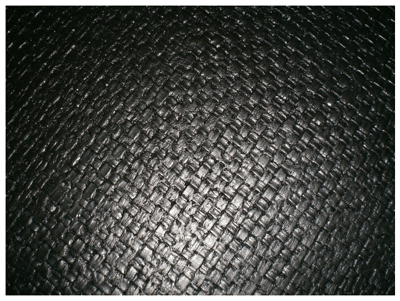

Slade Incorporated has become a globally recognized company with all manufacturing performed at our facility located in Statesville, North Carolina USA. Founder Bob Crosier started Slade by drawing on his lifetime of experience in the sealing industry. Originally, Slade was to become a yarn manufacturer, supplying the packing industry with the first braidable expanded graphite yarn. Slade patented this newly developed technology in both its design and the machinery used to produce the graphite yarns. In the years following, Slade not only produced that braidable expanded graphite yarn but also became a braided graphite packing manufacturer as well, the first of its kind. Slade has taken the raw materials of expanded graphite and high tensile strength carbon to form the finished product of a flexible, rope-style valve and pump graphite packing capable of high temperature and high pressure without the use of lubricating type binders.

Manufacturing Process Of Slade Sealing Products

Slade manufactures all of its own patented graphite yarns. The advantage is that each individual strand has its own unique core made of high tensile carbon fiber. Our yarns are protected by US & EU patents, and were developed to conduct heat like steel alloys, to transfer the heat away from the shaft. When Slade Foil is compressed by 25% (the denser the better), die-formed density is achieved in the stuffing box. This forms a “heat sink” in the stuffing box, eliminating the need for flush-water to cool the shaft sleeve in most applications. In addition, Slade reduces the number of oxidation sites in the packing yarns so that Packing can be used in more severe temperature and chemical applications than competitor’s packings.

Certified Slade Graphite Yarn Suppliers

High Quality Graphite Yarn & Braided Packings

When you order Slade products from us, you are going to get high-quality items from a globally recognized company. You will also be getting items that are produced in the United States – North Carolina, to be exact. The company was founded by a man who had a lifetime of experience in the sealing industry. This was one of the first products the company made – and it still excels at what it needs to do. If you need something that can withstand both high temperature and high pressure without needing lubricating type binders, then this is what you need. Our prices for these products are very affordable and you will get top-notch use from it. Feel free to contact us at B&W Distributors to learn more.

Leading Graphite Yarn Products In The Sealing Industry

Industrial-Grade Patented Graphite Packing

Do you have a system that involves valves, faucets, stuffing boxes or anything else that is watertight? Slade’s graphite packing is perfect to seal those systems to protect them.

High Tensile Strength Carbon Fiber Packing

Slade’s carbon fiber packing is perfect for pumps and valves that are used in high temperature applications. They will fit your unique needs and will work for a long time.

Resistance To High Temperature & Pressure

You need packing that is resistant to both pressure and high temperatures. We have the Slade products that can fit both of those criteria. Contact us to learn more.

Slade Suppliers Providing Efficient Industrial Solutions

Whatever you need from a Slade product, we have it. There are a lot of different options that will work for different scenarios. Do you have something that will operate under a lot of pressure? We have material that will withstand extremely high pressure and still do an excellent job of sealing up the items. They are perfect for all different kinds of industrial applications. The same goes for situations that will involve high heat. It will keep things working properly even with the highest temperatures. Do you have any questions? Feel free to reach out to us about how a certain item might be what you need or if there is a better alternative.

Water & Wastewater Industry

Slade also has products that will help companies efficiently and safely handle wastewater. These products also aid in the prevention of contamination. Contact us if you have any questions.

Power & Energy Sector

The experts at Slade know how important it is to properly seal off things at power and electrical companies. Their products help the people working there be assured that things like valves are protected.

Maritime Trade & Shipping Industry

Slade graphite yarns and foils are an excellent option for maritime and shipping industries, as they are highly resistant against thermal variations, being able to withstand temperatures of up to 1800°F/1000°C.

Refineries & Petrochemical Industry

Refineries and petrochemical companies need the best sealants for their valves and other machinery. They can operate under a lot of pressure and heat and those need to be sealed. Slade’s products can do just that.

Other Heavy Industrial Markets

There are many other markets that Slade has products for. If you are not sure if your company has a need for it, contact us today so that we can point you in the right direction.

Slade Products For Sale With Different Applications

We have a lot of Slade products that can do everything from assure that you are able to pack your pumps and valves and be assured that they will be leak-free. Their carbon graphite is excellent for high-pressure pumps and they can also transfer heat away from the shaft, which is important. The graphite yarn is extra reinforced and we also sell flexible compressor kits for packing. Their self-forming gasket joint sealants are excellent and the same can be said for their self-lubricating graphite foil sealing rings. Whatever your needs are, we have the Slade products on hand to make sure that your business will be able to handle whatever processes are required without any leakage or heat transfer problems. Do you have any questions? We will have answers for you. Reach out to us today to learn more.

Leak-Free Pump & Valve Packing

The last thing you want to worry about is your pumps and valves leaking. That won’t be a problem with Slade packing.

Carbon Graphite For High Pressure Pumps

When you are operating your high pressure pipes, you want to ensure that you have them working perfectly. Slade’s carbon graphite will do that.

Reinforced & Expanded Graphite Yarn

Slade always takes great efforts to reinforce their graphite yarn as well as expand them. You can use them with confidence.

Transfer Heat Away From The Shaft

When there is high heat along the shaft of piping, that can cause issues. Slade has products that will transfer that heat away.

Keep Solids Out Of The Stuffing Box

You want to ensure that your stuffing box only has liquid running through it. Slade’s products will keep solids out of it.

Flexible Packing Compressor Kits

The last thing you want is a stiff packing compressor kit. Slade’s flexible kits make the job easier for you.

Self-Forming Gasket Joint Sealants

You will be glad to see how Slade’s self-forming gasket joint sealants work. We offer them at very reasonable prices.

Self-Lubricating Graphite Foil Sealing Rings

Slade’s self-lubricating gasket joint sealants make maintaining the gaskets much easier. You won’t have to constantly monitor them like before.

Our Clients’ Reviews

Slade Distributors Serving Nationwide

What a great family owned business!! I am partial as their employee but their industry knowledge and business standards and ethics are unmatched! You won’t find a better business to work with and their product line is top notch and superior to other product lines.

Leah B. ★★★★★

Great experience! Our B&W Distributors representative took time to explain all the applications that would suit our needs. The company was extremely professional throughout the entire process, from the initial call to the completion of the project. Highly recommend.

Katherine J. ★★★★★

Very helpful. The person I talked to took the time to explain my options for the type of industry I’m working with. Their staff is friendly and easy to talk to. I 100% recommend them!

Andy G. ★★★★★

Licensed Slade Distributors Near You

Experienced & Reliable Graphite Yarn Distributors

We are very reliable when it comes to selling Slade products. We keep a careful eye on inventory and we also sell them at very reasonable rates. Our staff is very knowledgeable about a wide range of things, including packing material, how they react to certain scenarios, and what you would need for yourself or your business. We know how important it is for certain facilities to keep working all the time. Contact us for a consultation or if you have any questions about Slade. We are glad to help you. Reach out to us today.

High Quality Pump & Valve Sealing Products

Slade has excellent products if you need to scale your pump or valve. They will help improve the efficiency.

Industrial Grade Packing Made Of Durable & Strong Materials

When you get a Slade graphite packing product, it will be extremely durable and you can use them knowing that it will do its job.

Graphite Packing With Excellent Impact & Chemical Resistance

Slade makes its products to withstand impacts and also resist chemicals that could otherwise erode the material that it is protecting.

Reinforced Yarn For Higher Resistance To Chemicals & Oxidation

Oxidation is something that can do a number on pipes. The same can be said for chemicals. Slade’s yard resists both.

Why Choose Our Slade Packing Dealers

Cost-Effective Industrial Pump & Valve Sealing Solutions

You want to run your industrial facility as smoothly as possible. That can cost money and eat into your budget. That won’t be a problem if you get Slade products through us. We have them at some very excellent prices that will make you happy. Then the people maintaining the valves and pumps will be thrilled at how well they are sealed. Contact us today, let us know about your budget, and we will do everything that we can to make you happy. See why we consistently get high recommendations from people in the industry.

Contact A Professional Slade Distributor Near You

2702 N Ogden #107

Mesa, AZ 85215

341 Stealth Ct.,

Livermore, CA 94551

Email: info@bwdist.com

Office Hours

Monday – Friday

8:00am to 4:30pm