How To Protect Your Pipelines From Corrosion

Effective Maintenance Practices To Prevent Corrosion In Industrial Pipelines

Corrosion in pipes is a risk that companies cannot afford to take. This is especially true for those in the chemical, oil, or energy industries, which handle products and materials that can have a devastating impact in the event of problems. For example, environmental pollution, unexpected failures, or even toxic leaks.

This represents a huge danger for your employees and your own business. After all, operational disruptions mean millions in repair or replacement costs. For this reason, it is essential to learn how to manage and prevent corrosion through good maintenance practices. Here we tell you how to apply effective solutions to the problem.

The Importance Of Preventing Pipeline Corrosion In Industrial Operations

Industrial pipelines transport all kinds of materials that are critical to the operation of your industry. These can be natural gas, chemicals, wastewater, or even oil. In any case, the problem is that they can react with the metal, weakening its structure over time.

If we also consider that many pipelines are decades old, an even bigger problem arises. The possibility of deterioration is higher! For this reason, it is essential to have reliable systems that can reduce the occurrence of internal and external corrosion. This way, you can save yourself headaches before they arise.

What Causes Corrosion In Industrial Pipelines?

Corrosion can often be caused by a variety of factors. The most common are as follows:

- Exposure to oxygen and temperature variations, which can cause moisture. Moisture is not good for pipes!

- Contaminants present in the fluids being transported or bacteria that degrade the metal. In such cases, it is necessary to analyze what is happening with those fluids.

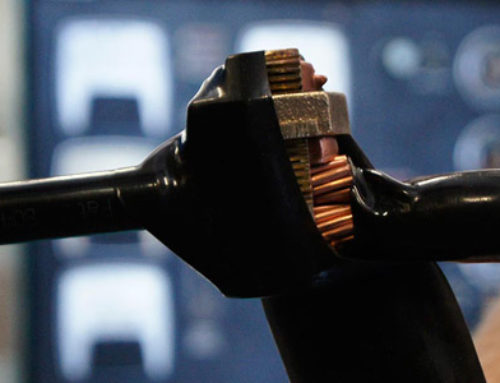

- Contact between different metals, which can cause galvanic corrosion. Abrasion can also occur in vulnerable areas.

The problem with corrosion in pipes is that once it starts, it spreads. This shows why it is important not only to repair the damage, but also to anticipate it. To achieve this, it is always essential to have a pipeline corrosion protection products distributor that can meet your demand.

What Types Of Corrosion Are Found In Pipes?

Corrosion can be divided into two types according to its characteristics. Let’s analyze the most common types:

1. Internal Corrosion

This occurs due to the elements contained in the fluids transported through the pipes, leading to internal corrosion. For example, with water, carbon dioxide, oxygen, chlorides, or hydrogen sulfide. It is usually a very dangerous form of corrosion, as it is difficult to detect or prevent, except when the problem is already too obvious.

2. External Corrosion

The external corrosion occurs due to various factors, such as mechanical friction, contaminants, or moisture. It occurs due to the interaction between the external wall of the pipe and environmental or external factors. In general, it spreads evenly, both throughout the pipes and in weakened areas.

Effective Solutions To Protect Your Pipelines From Corrosion

If you are hoping for a magic or universal solution for your pipes, you should know that it does not exist. You need to implement a comprehensive strategy to protect your pipes! Below are some strategies for extending the useful life of your pipes:

1. Cathodic Protection Systems

This is a fairly effective method that allows the metal to lose electrons. In other words, corrosion begins to stop. It usually works thanks to external current. When combined with coatings, Cathodic Protection Systems are a great way to protect underground pipelines. However, to ensure its effectiveness, monitoring is necessary to evaluate current levels, as well as prior studies of the soil or environment.

2. Control Of Contaminants In Transported Fluids

It is very important to reduce contaminants to avoid long-term problems in pipelines. If you minimize corrosive elements, you will slow down the rate of degradation. To do this, it is necessary to deoxygenate the fluid before it enters the pipeline, remove condensed water, and filter out suspended solids. All this is done so that the fluid reaches the pipeline completely clean, reducing risks!

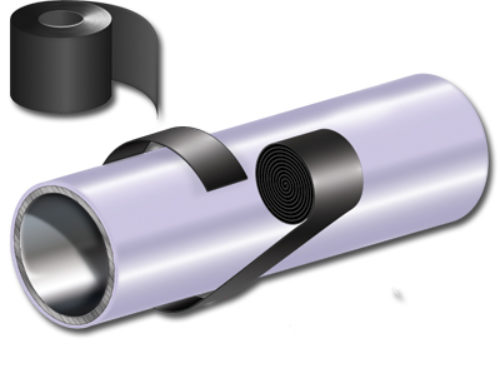

3. Application of Coatings & Coverings For Protection

This is one of the most widely used methods. It consists of creating a resistant barrier between the metal and any corrosive elements that may exist. This offers clear benefits, such as protection against moisture and abrasion or high chemical resistance. Even in extreme conditions, long-term durability can be guaranteed.

You can do as many other companies have done and look for an epoxy distributor in the US Southwest. This will give you the peace of mind of having quality products when you need them most.

4. Internal Cleaning & Sediment Removal

Localized corrosion is often caused by the presence of bacteria or debris. As you might imagine, there is a solution for this: cleaning! Pigging, or internal cleaning, improves material flow and reduces the likelihood of corrosion under deposits. However, for this to work, it is not enough to do it just once. It must become a regular cleaning routine.

5. Ensure Pipe Stability & Avoid Friction

Any situation that causes friction can increase existing corrosion or even cause it. Microcracks, over time and with wear, can exacerbate the problem. To avoid this, perform structural integrity inspections and try to minimize vibrations in nearby equipment. The key is to achieve stability in the pipeline to reduce the risk of corrosion.

Physical wear can also accelerate corrosion. Vibrations, shocks, friction, ground movements, or thermal expansion can cause microcracks that become vulnerable points.

6. Avoid Contact Between Incompatible Metals

When two incompatible metals come into contact in the presence of an electrolyte, what is known as “galvanic corrosion” occurs. This causes rapid degradation, which can lead to corrosion. To avoid this, always choose compatible materials. It is also essential to insulate connections.

7. Corrosion Inhibitors & Advanced Technologies

When you use inhibitors, the rate of corrosion is reduced. This is a great way to progressively stop the problem, especially in pipelines where internal coatings cannot be applied. What are inhibitors? Simple, liquids or vapors. More specifically, vaporizers known as VCIs (Vapor Corrosion Inhibitors), which act as a film against water and oxygen.

8. Use of Sealants, Adhesives & Specialized Repair Materials

Finally, beyond maintenance, it is important to repair localized damage. To do this, you can use an industrial coating supplier, who can help you by providing quality materials. For example, advanced epoxy compounds can be used to fill cracks or reinforce weakened areas.

Contact B&W Distributors For Expert Pipeline Protection Solutions

Corrosion in pipes is not something you should ignore. As we mentioned, it poses a multitude of risks. Maintenance may be easier than you think, but the important thing is to have a comprehensive approach and the proactivity necessary to sustain it over time. This way, you’ll avoid problems such as increased costs and insecurity in your daily production operations.

Want to strengthen the protection of your pipes? Contact B&W Distributors, INC. We have a team that can offer you expert advice to keep your infrastructure stable and in the best possible condition. Contact us now!

B&W DISTRIBUTORS INC.

Tel: (480) 924-8883

Email: info@bwdist.com

Web: https://www.bwdist.com/

ARIZONA

2702 N Ogden #107

Mesa, AZ 85215