Wax-Tape® HT-3000

High-Temperature Anticorrosion Wrap

An easy-to-apply protection system for high-temperature applications, Wax-Tape® HT-3000 wrap requires minimal surface preparation.

Effective on straight pipe. Wax-Tape HT-3000 wrap can also be used on irregular- shaped valves and fittings.

Trenton Wax-Tape® HT-3000 high-temperature anticorrosion wrap is a specially formulated wax-based wrap used for corrosion protection of metal pipe and fixtures experiencing higher than normal temperatures. When used in combination with Trenton TemcoatTM 3000 primer, this easy-to-apply wrap delivers highly effective and durable corrosion protection to bare or coated surfaces in a wide range of field conditions.

End Use:

Wax-Tape HT-3000 wrap can be applied and will perform effectively at continuous operating tempera- tures of up to 230°F (110°C) and is designed for use in aboveground and belowground applications.

Features:

Easy of use:

- Quick and easy to apply, with minimal equipment requirements

- Can be applied to surfaces with minimal preparation (SSPC SP2 or ISO St2)

- Can be applied in high-moisture conditions.

- Can be applied at “in-service” temperatures

- No cure time – ready for immediate backfill after application

- Non-toxic – no Volatile Organic Components (VOCs)

Proven durability and performance of Trenton Wax-Tape Systems:

- Trenton Wax-Tape® anticorrosion wrap systems have over three decades of successful field performance

- May be used aboveground or belowground (UV resistant)

- Resistant to acid, salts, and other soil organics over a wide range of pH

- High dielectric strength

- Excellent resistance to cathodic disbondment

Typical Applications:

- High-temperature oil and gas production piping

- Gas pipeline compressor station discharge piping

- Refining and petrochemical process piping

- Beneath thermal insulation on piping

- Locations and environments with consistently high (> 110°F / 44°C) ambient temperatures

Application Procedures:

Surface Preparation:

- Remove all loose rust, scale, paint, ice, dirt and other foreign matter with a wire brush (SSPC SP2, ISO St 2). Wipe surface dry, if possible.

Tape and Primer Application:

- Coat pipe surface with Trenton TemcoatTM 3000 primer by hand, ensuring an even, continuous film of primer over all exposed metal surfaces to be wrapped.

- With a downward-facing starting point, wrap Trenton Wax-Tape® HT-3000 wrap onto pipe in a spiral pattern using a minimum 1” overlap. When wrapping, apply tension and press the wrap onto surface.

- After wrapping, rub the entire surface of the wrap to remove any air bubbles and to smooth the surface. Press the overlap seams and ensure they are sealed and tapered, especially on each end of wrap application.

- If ambient work site temperatures are below 50°F, keep wrap warm before application.

- Trenton MCOTM outerwrap should be used for applications requiring substantial mechanical protection or where contact with the sticky exterior might be a problem.

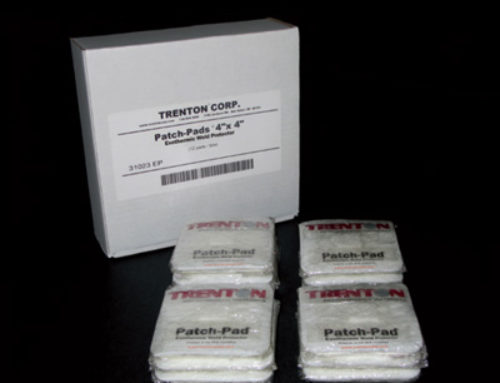

Packaging:

2” x 9’ (5cm x 2.7m) rolls (48 rolls/case)

4” x 9’ (10cm x 2.7m) rolls (24 rolls/case)

6” x 9’ (15cm x 2.7m) rolls (16 rolls/case)

12” x 18’ (30cm x 5.4m) rolls (4 rolls/case)

Specifications:

| Properties | English | Metric |

|---|---|---|

| Thickness (ASTM D1000) | 100 mils | 2.5mm |

| Maximum substrate operating temperature | 230°F | 110°C |

| Maximum substrate application temperature | 230°F | 110°C |

| Minimum substrate application temperature | 30°F | -1°C |

| Siliceous Mineral filler content (%) | None | |