Industry Solutions

Oil & Gas

Harsh environments in the Oil and Gas Industry can cause corrosion to pipes, valves and structures. All aspects of drilling and pipelines will experience wear and degradation and need to be protected to prevent corrosion and erosion from reducing life span, strength and reliability. The key to solving these problems is to select solvent-free polymeric materials that outperform conventional materials.

Refineries

Of all the problems that could affect a Petrochemical Refinery, corrosion is the one that is most challenging. The environment in a Refinery is a complex liquids and gases interface characterized by temperature fluctuations and chemical reactions. This activity is bound to take its toll on piping, pumps, tanks and other vessels.

Power

Power generating systems often experience fowling and corrosion that challenge efficiency and productivity. Surface protection for condensers, water boxes, heat exchangers, intake and outtake water pipelines and tunnels, pumps, basins, and traveling screens must be addressed using superior products that eliminate galvanic corrosion problems, abrasion and erosion losses, and ground water in-leaking.

Mining

Corrosion and erosion reduce strength, reliability and life span of structure and equipment in the mining industry because of the corrosive properties of the materials processed, as well as the abrasive mining environment. Our coatings offer chemical resistance, thermal resistance, abrasion resistance, physical abuse resistance, general corrosion resistance, UV resistance, and flexibility.

Water

At B&W Distributors, we have products to protect internal tank surfaces against corrosion, leaching and leaks, maintaining water quality and preventing loss of drinking water. In addition, we protect against negative water ingress in subterranean tanks, systems to repair and protect steel and concrete tanks in contact with potable water, and linings to stop the ingress of ground water into underground tanks.

Waste Water

For the best waste water industrial solutions in the southwest, consult with the authorized dealers at B&W Distributors, Inc. Offering many alternatives for high performance linings, coatings, and adhesives, you can protect your internal tank surfaces to prevent leaks and ensure that your equipment remains intact from the continual flow of corrosive materials. Browse our selection today.

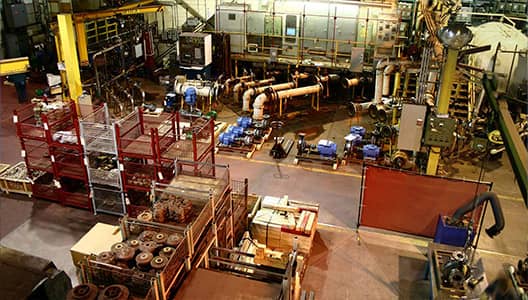

Manufacturing

Not surprisingly, corrosion and wear are common problems in manufacturing due to the harsh atmospheric environment and the corrosive properties of the liquids, slurries and other elements consumed throughout the manufacturing process. Critically important equipment and structures need to be protected correctly or this corrosion and erosion will reduce the structure’s strength, reliability, life span and, ultimately, its economic value.

Other Industry Solutions

B&W Distributors carries a line of coatings that can be applied to protect equipment and machinery in many environments, facilities and factories. Customers nationally are selecting high performance coatings because they significantly outperform conventional solvent-based or hazardous coatings. Our products meet the stringent regulations required by industry standards.